Aluminum Nitride, represented by the formula AlN, belongs to the family of advanced technical ceramics and possesses a covalent bond with a hexagonal crystal structure. This material boasts exceptional thermal, mechanical, and electrical properties, including high thermal conductivity, low dielectric constant, high electrical resistivity, low density, and a thermal expansion coefficient that closely matches that of silicon. Its primary application is as a substrate for electronics or chip carriers, and it is also utilized, alongside PBN crucibles, in the construction of crucibles for growing GaN (gallium nitride) crystals.

Aluminum nitride crucibles demonstrate remarkable resistance to oxidation in air up to 1300°C, though oxidation initiates after 700°C. In a vacuum environment, AlN decomposes at 1800°C, while its melting point is 2200°C under inert atmosphere protection. Generally, AlN products can be safely used up to 800°C in air, 1700°C in vacuum, and 2100°C in an inert atmosphere.

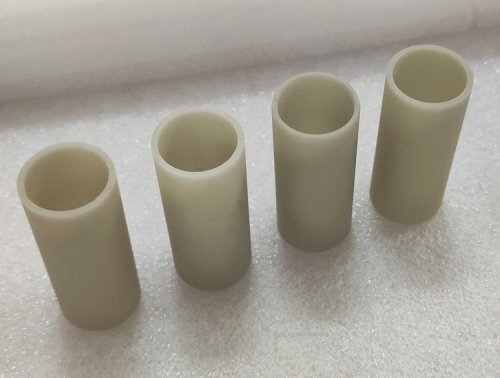

These ceramics find applications as containers for vacuum evaporation and metal smelting, particularly well-suited for vacuum evaporation crucibles for aluminum. This is due to their ability to resist decomposition in a low vapor pressure vacuum, preventing aluminum contamination. In the semiconductor industry, substituting quartz crucibles with aluminum nitride crucibles for synthesizing arsenide eliminates Si pollution on GaAs, ensuring the production of high-purity products.

However, it is important to note that aluminum nitride ceramics react chemically with inorganic acids, strong bases, water, and other liquids, causing slow dissolution. Thus, they should not be directly immersed in such substances. On the contrary, these ceramics can withstand the corrosion of most molten salts, including chlorides and cryolite (Na3AlF6).

Due to the small bottom size of aluminum nitride crucibles, they are typically placed on a clay triangle during heating and should not come into direct contact with metal or wooden supports after intense heating. Furthermore, sudden cooling after heating should be avoided, and instead, the crucibles should be allowed to cool naturally on the clay triangle or gradually on asbestos gauze before handling them with a crucible tong.

Stirring the substance until nearly evaporated, then turn off the heat, and steam it with the remaining heat.