The high purity quartz sand and ultrafine quartz powder industry is faced with insufficient fineness, uneven mixing, poor dispersion, and excessive impurities long-term problems. These issues have long plagued the production of advanced quartz-based products used in sectors like solar energy, semiconductors, and photovoltaics. Silicon nitride (Si3N4) grinding media offers a reliable solution to these chronic industry problems and improving production efficiency and product quality.

Advantages of Silicon Nitride Ceramic Media in Grinding Photovoltaic Quartz Crucibles and High-Purity Quartz Products:

High Hardness and Low Wear

Silicon nitride ceramic grinding media Vickers hardness is 14-18 GPa (second only to diamond and cubic boron nitride), enhances the purity, quality, and value of high-purity quartz sand and superfine quartz powder. It also offers superior performance compared to traditional materials like zirconia and agate in terms of compressive strength, thermal expansion, and heat tolerance.

Minimal Abrasion and Material Contamination

After 24 hours of grinding, the wear rate of silicon nitride grinding media is extremely low—just one part per million. This minimal abrasion reduces material contamination, resulting in higher purity ultra-fine quartz powders.

Long Service Life and Cost Efficiency

Silicon nitride grinding media has an exceptionally long lifespan, with some products maintaining effectiveness for up to 20 years. Although the initial cost of silicon nitride media may be higher, its longevity and low wear rates lead to reduced overall production costs for quartz products.

Sustained Performance Over Time

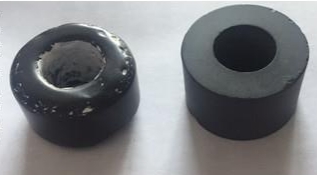

Even after a decade of continuous use, silicon nitride grinding media shows minimal wear, with surfaces becoming smoother but retaining their structural integrity. This durability offers long-term economic benefits when considering the total lifecycle cost.

After 10 years of work & Not working

After 10 years of work & Not working

Enhanced Grinding Efficiency

Silicon nitride grinding balls improve the fineness, homogeneity, and dispersion of quartz powders, while minimizing particle agglomeration. These properties make silicon nitride particularly suitable for vertical and horizontal planetary mills, vibration grinders, and other precision grinding equipment used in the production of high-purity slurries and powders.

Applications:

Silicon nitride ceramic media is ideal for wet and dry ultra-fine grinding and dispersion in industries with stringent purity requirements. It can be used across various equipment types, including vertical mills, horizontal ball mills, and V-type mixers.

Inlabs offers mass production of silicon nitride ceramic grinding rings,silicon nitride ceramic grinding balls, and customized products are available, welcome to contact us at welcome to contact us at sales@inlabs.cc.