Alumina Ceramic Grinding Balls: The Key to High-Precision Milling and Grinding

Alumina Ceramic Grinding Balls can be used both in the laboratory and industries because of their strong performance and reliability. They are vital in a number of applications encompassing, chemical synthesis and materials science up to food and pigment industries.

Alumina ceramic grinding balls are fabricated from high purity bauxite (Al2O3) which enables them to perform extremely well in various applications but particularly where hardness, wear resistance, and chemical stability are a challenge. Some of the major benefits are as given below:

1. Exceptional Hardness and Wear Resistance

These balls have high wear resistance and can survive even extended grinding operations without breaking. High efficiency grinding is hence possible even for the hardest materials.

2. High Chemical Resistance

Alumina ceramics are quite chemically durable towards almost all acids, alkalis, solvents, and other chemicals that come into contact with them, which makes them useful in many chemical reaction and synthesis processes.

3. High Temperature Withstanding Ability

These materials can maintain their integrity and form at very high temperatures for prolonged periods, which is favorable for processes that use high temperature grinding.

4. Controlled Levels of Contaminations

Because of their high purity, they do not contaminate the grinding media introducing unwanted materials into the experimental materials. This is important when synthesizing materials and superior quality chemicals that require high precision.

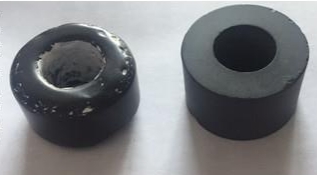

Alumina ceramic grinding balls vs Zirconia ceramic grinding balls Which is More Effective

One of the more common options are Zirconia Ceramic Grinding Balls while making selections among grinding media. The main differences are:

Application Areas

1. Chemical and Pharmaceutical Industries

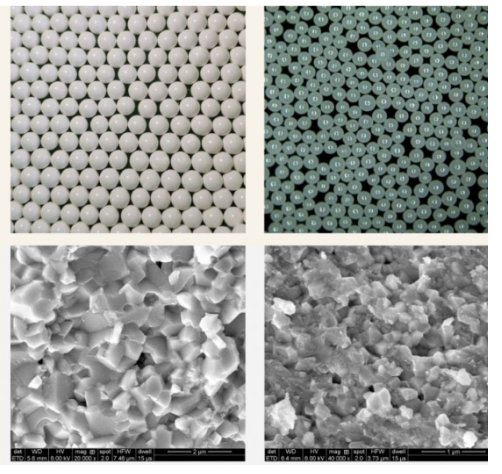

There are instances when alumina milling jars are combined with ceramic grinding balls in a chemical synthesis process in order to increase efficiency and quality practice. In the production of precision chemicals and medical materials, the alumina balls low contamination feature is very critical.

2. Materials Science and Nanotechnology

The sythesis of particle size and shape in competitive materials is a vital prerequisite in materials research and nanotechnology. Owing to their high particle uniformity and even hardness, alumina balls have found numerous applications in the high-precision grinding of zirconia milling jars.

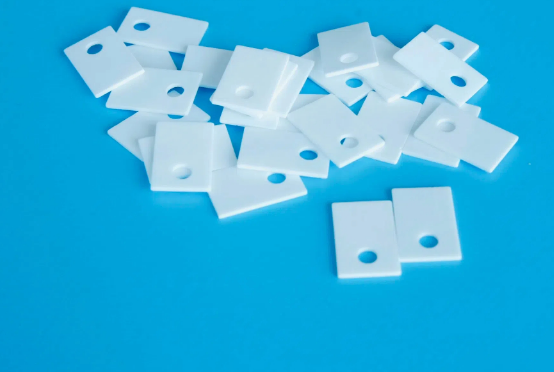

3. Paint and Coating Production

Grinding with ceramic balls can enhance consistency and finesse in the processes of making synthetic paints, coatings, and pigments. Their resistance to impact and their high efficacy in grinding make them suitable for use mostly in practice.

4. Food and Beverage Processing

Within the food processing practice, spices and seasonings are gotten crushed using alumina balls, these balls are said to be highly wear resistant and low contamination hence maintaining the quality of the end product.

Requisite Considerations When Selecting the Right Ceramic Grinding Ball

Facility: How should one go about choosing a ceramic grinding ball? Many specialists consider the factors listed below:

1. The Size and Size Distribution of Aluminum Oxide Grinding Balls

In the case of highly hard materials, Zirconia Ceramic Grinding Balls may be used. But for general purposes, Alumina Ceramic Grinding Balls would suffice.

2. Price and Performance:

If the price is critical, it is reasonable to state that Alumina Ceramic Grinding Balls are the preferred choice as they are relatively economical.

3. The Chemical Environment:

Select the required ceramic material depending on temperature and chemical environment needed. Both alumina and zirconia can withstand high temperature or corrosive environments.

Practically speaking, when used in high efficiency grinding applications, Alumina Ceramic Grinding Balls stand out because of their excellent hardness, wear and chemical stability and low contamination. In chemical synthesis, materials research, food processing and paint production, these ceramic grinding balls perform a formidable task of grinding and providing high and efficient quality. Thus, knowledge of different ceramic grinding balls properties helps in selection of ceramic grinding balls of one’s choice.