The Origin and Development of Silicon Nitride Ceramics

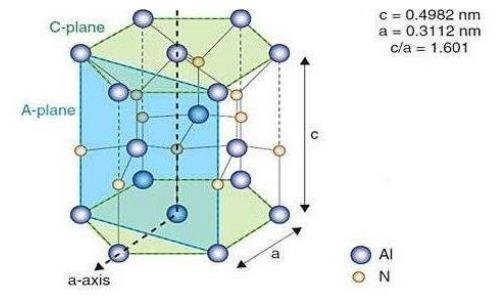

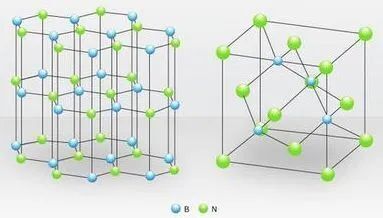

Silicon nitride (Si3N4) is a covalent bond compound composed of silicon and nitrogen. It was discovered in 1857, but some scholars, especially German researchers, did not fully agree with its chemical composition. Later, a large amount of research confirmed the correctness of this chemical formula, which has been widely cited until now.

Next, we will introduce the important applications of silicon nitride ceramics from four fields.

The soul of No.1 rotating machinery, the carving knife of mechanical components

Silicon nitride ceramics have a wide range of applications in mechanical fields such as high-speed turning tools, bearings, engine blades, guide blades of gas turbines, and turbine blades.

Among them, bearing balls are the most widely used silicon nitride ceramic products, accounting for three tenths of the world”s high-performance silicon nitride products in annual production. Silicon nitride ceramic bearing balls have outstanding advantages compared to steel balls: low density, high temperature resistance, self-lubrication, corrosion resistance, and the same fatigue life failure mode as steel balls. As a high-speed rotating body, ceramic balls generate centrifugal stress, while the low density of silicon nitride reduces the centrifugal stress on the high-speed rotating outer ring. Dense Si3N4 ceramics also exhibit high fracture toughness, high modulus properties, and self-lubrication, which can resist various types of wear and endure harsh environments that may cause cracks, deformation, or collapse of other ceramic materials, including extreme temperatures, large temperature differences, and ultra-high vacuum. Therefore, silicon nitride ceramic bearing balls can be widely used in fields such as precision bearings for machine tools, automotive bearings, insulated bearings for wind turbines, corrosion-resistant and high-temperature bearings for petrochemical industry.

Especially, in addition to these excellent properties, silicon nitride bearings also have insulation properties, which can solve the problems of electrical corrosion often causing bearing surface damage, premature aging of lubricants, and abnormal noise, avoiding shortening the service life of bearings and lubricants, ultimately leading to bearing failure. They are very suitable for applications in fields such as electric vehicles.

Another classic application of silicon nitride ceramics in the mechanical field is high-speed cutting tools.

NO.2 wear-resistant and corrosion-resistant field, very resistant to beating

Silicon nitride ceramics have excellent corrosion resistance and wear resistance. Their excellent creep resistance, oxidation resistance, and low thermal expansion enable silicon nitride ceramics to meet the harsh conditions of application. In addition to bearings and cutting tools, the wear-resistant and sealing components of silicon nitride ceramic materials can also be applied in many harsh environments. The silicon nitride ceramic prepared by the hot pressing process in Saint Gobain, France has good high-temperature strength, corrosion resistance, and creep resistance. It is an ideal sealing surface material in the nuclear industry and can be applied to boiler reactor water pumps, pressure water reactor water pumps, and corrosive boric acid water treatment, It can also be applied to rotating components such as compressors, engines, generators, motors, and turbines.

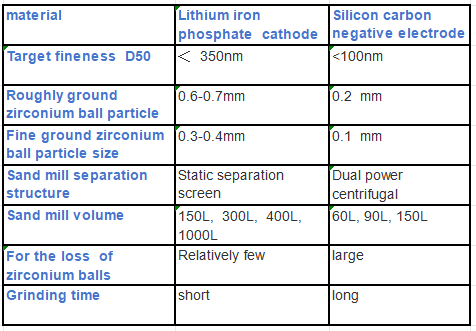

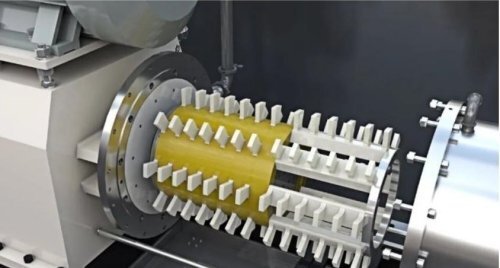

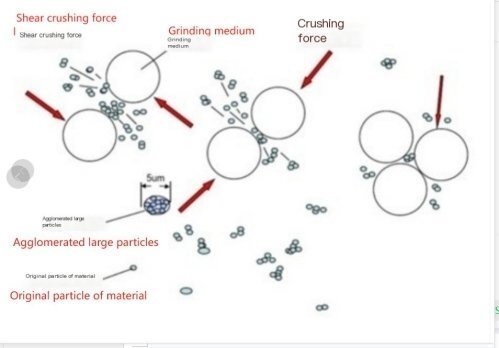

In addition, silicon nitride also holds a place in the field of ultrafine grinding. Silicon nitride has high hardness, second only to a few superhard materials such as diamond and cubic boron nitride, and has low friction coefficient and self-lubricating properties. In the ultra-fine powder and food processing industries, the performance of silicon nitride ceramic grinding balls is higher in hardness and superior in wear resistance compared to traditional grinding balls.

NO.3 Aerospace field, very reliable in harsh environments

Silicon nitride ceramic materials have advantages such as high strength, high temperature resistance, and good chemical stability, which can meet the stringent requirements of materials in the aerospace industry. Silicon nitride ceramics have two classic applications in the aerospace field:

firstly, silicon nitride is considered one of the few monolithic ceramic materials that can withstand severe thermal shock and thermal gradients generated by hydrogen/oxygen rocket engines, and is used in rocket engine exhaust nozzles. In 2010, the tail nozzle of Japan”s space probe Akatsuki thruster was made of silicon nitride material, and the silicon nitride tail nozzle prepared by Kyocera has been successfully applied to small aircraft and rocket engines. Compared to metal materials, silicon nitride ceramic nozzles can withstand higher combustion temperatures, allowing the thruster to obtain greater thrust. The high stability of the nozzle edges makes the jet airflow more uniform.

The second is to serve as bearings for aviation engines. In the design of aircraft engines, bearing materials and technology always account for over 90% to 95%. It can be said that bearing technology represents the ultimate speed, temperature resistance, and reliability level of the engine. Ceramic bearings, with their excellent performance, can provide important basic technical support for the development of the aviation equipment field, especially the hot isostatic pressing sintered silicon nitride ceramic bearings, which provide core technical support for the development of aerospace. After more than 50 years of research and accumulation, Si3N4 ceramic bearings have been applied in helicopter main transmissions, aviation APUs, aircraft accessory transmissions, missile engines, rocket engines, and aerospace satellites, becoming standard bearings for high-speed and high-power spindles in high-end manufacturing equipment.

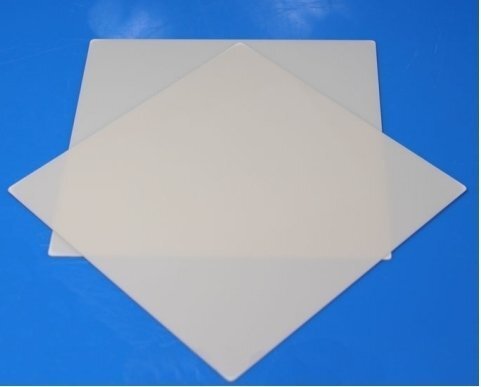

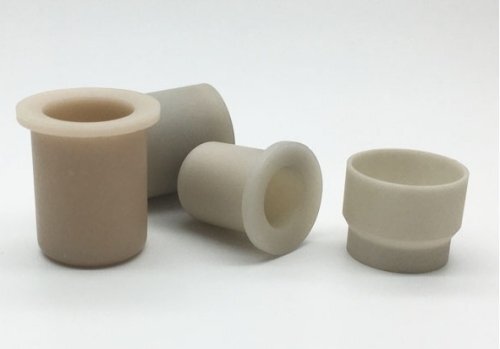

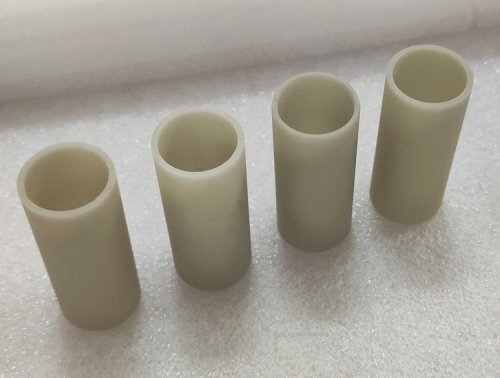

NO.4 chemical and metallurgical industry, fearless of 1400 ℃ high temperature test

Silicon nitride ceramic materials have excellent chemical stability and mechanical properties, and can be used as components in thermal equipment such as crucibles, combustion nozzles, and aluminum electrolytic cell liners in the metallurgical industry. Silicon nitride ceramics have good oxidation resistance, with an oxidation resistance temperature of up to 1400 ℃. They remain stable in a dry oxidation atmosphere below 1400 ℃ and can be used at temperatures up to 1300 ℃. And silicon nitride materials can be applied in environments with rapid cooling and heating, so they also have extremely wide applications in the metallurgical industry.