With the increasing fineness requirements of materials, the use of sand mills is becoming more and more common, and there are more grinding media in the market. How to choose a grinding media that is more suitable for its own production process and conditions is a key and laborious matter. Here is a brief analysis of the following aspects.

I. Chemical composition

Grinding media can be divided into glass beads ceramic beads (including zirconium silicate beads composite zirconium beads alumina beads rare earth metal stabilized zirconia beads, etc.), steel balls, etc. according to different materials. Due to the difference of chemical composition and manufacturing process, the crystal structure of the grinding bead is determined. The dense crystal structure ensures the high strength, high wear resistance and low ink absorption of the bead. The different percentage contents of various components determine the specific gravity of grinding beads, and the high specific gravity provides guarantee for high grinding efficiency; the natural wear of the chemical composition of grinding beads in the grinding process will have a certain impact on the performance of slurry, so in addition to considering the low wear rate, the chemical elements to be considered are also factors to be considered. For example, when grinding tape powder or other electronic component slurry, metal elements such as Fe and Cu should be avoided, and grinding beads containing Fe2O3 or CuSO4 are not included in the selection, so choosing zirconium beads is often the general choice in this industry; for example, in the aspect of grinding pesticides, medicine and Biochemistry, heavy metals are the most common elements to be avoided, while PbO is the most common one In a word, some physical properties (hardness, density, wear resistance) determined by the chemical composition of the beads and the pollution of its own abrasion to the slurry are the factors to be considered when choosing the grinding medium.

II.Physical properties

1. Density of grinding medium

Density is expressed by specific gravity (true specific gravity) and bulk weight (false specific gravity) in general documents. The molecular weight and percentage composition of various oxides determine the grinding density. The density of commonly used grinding media is shown in Table 1.

In general, the larger the specific gravity of the grinding beads, the larger the impulse, the higher the grinding efficiency, and the greater the wear of the contact parts (inner cylinder, dispersion plate, etc.) of the grinder, so the matching of the viscosity and flow of the slurry becomes the key. Low density abrasive beads are suitable for low viscosity slurry, and high density abrasive beads are suitable for high viscosity slurry.

2. Particle size of grinding medium

The size of the grinding bead determines the number of contact points between the grinding bead and the material. The larger the contact points of the beads with small particle size under the same volume, the higher the grinding efficiency theoretically. On the other hand, when grinding the materials with large particles in the initial test, for example, for the slurry with 100 microns, the beads with d = 1mm are not necessarily used, because the impulse of the beads can not reach the energy of full grinding and dispersion, At this time, beads with larger particle size should be used.

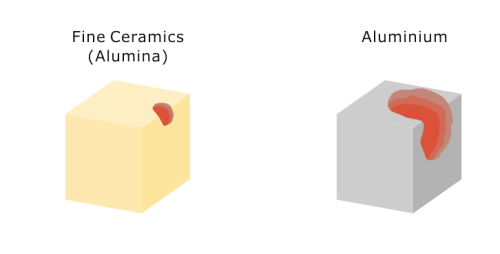

3. Hardness of grinding medium

Mohs and Vickers are commonly used indexes. The higher the hardness of the grinding beads, the lower the wear rate of the beads does not mean. The hardness of commonly used grinding media and other materials is shown in Table 2.

For example, from the point of view of the wear of the contact parts of the grinding ball to the grinder (such as the dispersing disc, bar pin and inner cylinder), the wear of the contact parts of the grinding ball with large hardness is larger, but the best optimization point can be achieved by adjusting the filling amount of the ball, the viscosity of the slurry, the flow rate and other parameters.

Finally, I hope this article can help you to deepen your understanding of the preferred raw materials for the preparation of zirconia bead . If you want to know more about it, please visit our website for more information, we can provide you with zirconia bead products and professional knowledge solutions.