Alumina can be divided into high-purity type and common type. The purity of high-purity alumina Al₂O₃ is greater than 99%, and the sintering temperature is as high as 1650 ° C to 1990 ° C. The purity of ordinary alumina Al₂O₃ is less than 99%, and sometimes Al₂O₃ with a purity of 80% or 75% is also classified as ordinary alumina series.

High-purity alumina is the basic material for producing heat-resistant, wear-resistant and corrosion-resistant products. High-purity 99% alumina is usually used to make high-purity alumina crucibles, integrated circuit substrates, special wear-resistant materials, etc., which cannot be achieved by ordinary alumina. Ordinary 95% alumina is mainly used as wear-resistant parts, and 85% alumina is often mixed with some talcum powder to improve electrical properties and mechanical strength. It can be sealed with metals such as molybdenum, niobium, and tantalum, and some are used as electric vacuum devices.

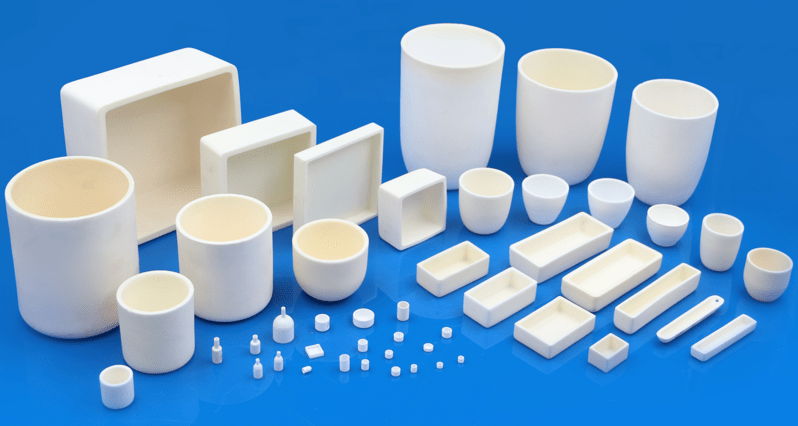

We can customize high purity crucibles in a variety of shapes and sizes, making high purity alumina crucibles perfect for a variety of applications. Including: powder heat treatment, lithium battery cathode material heat treatment, electronic products and phosphor powder sintering, piezoelectric and dielectric electronic material heat treatment, chemical analysis, etc.

Finally, I hope this article can help you to deepen your understanding of the preferred raw materials for the preparation of high-purity alumina crucibles. If you want to know more about it, please visit our website for more information, we can provide you with high-quality alumina crucible; products and professional knowledge solutions.