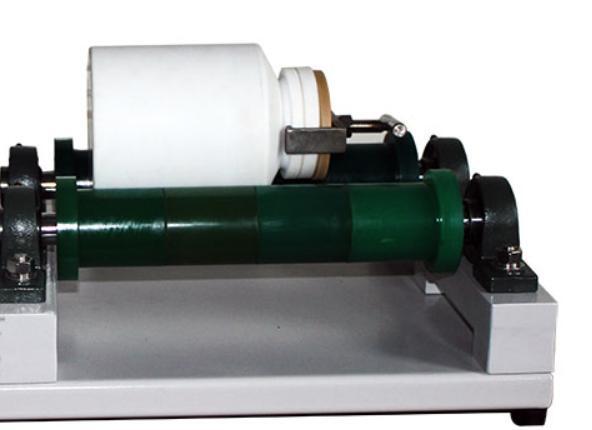

The ball mill machine stands as one of the most advanced powder grinding apparatuses currently available, widely employed across industries such as electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, and environmental protection. Its innovative design, compact footprint, and multifunctional capabilities render it indispensable in various departments. However, achieving fine grinding outcomes relies significantly on the operational integrity of Milling Jars. Over time, users may encounter a buildup of materials on the surfaces of the zirconia ceramic ball mill jars tank, presenting a persistent challenge. Presented below are several professional cleaning methods to address this issue effectively.

- Water Washing:

The simplest and gentlest method involves rinsing with water and incorporating a mild detergent, ensuring thorough cleaning without compromising the integrity of the grinding balls or the tank body.

- Detergent Washing:

For substances resistant to water-based cleaning, such as oils and solvents, a combination of laundry detergent or soapy water with the grinding balls and water can be rotated within the ball mill, effectively dislodging stubborn residues without causing damage.

- Ultrasonic or Plasma Cleaning Machine:

Employing mechanical means, ultrasonic or plasma cleaning proves effective against oils, viscous substances, and other tenacious residues, utilizing their powerful capabilities to disintegrate attachments and achieve optimal cleanliness.

- Acidic Washing with Sulfuric or Nitric Acid:

In instances where particularly stubborn residues persist, a judicious application of dilute acids, such as sulfuric or nitric acid, can be employed. This method, albeit aggressive, is reserved for specific circumstances and necessitates careful handling to ensure safety and equipment integrity.

- Solvent-Based Cleaning:

Tailored to materials processed in a wet ground state, solvent-based cleaning aligns with the principle of using compatible solvents for effective residue removal, thereby restoring the milling environment to its original state.

Primarily applicable in mechanical alloying studies, where alloy layers may form on tank walls and grinding balls, this method employs a combination of construction sand, quartz sand, or small corundum balls with water for comprehensive cleaning. This approach is particularly effective in addressing challenging residues.

Mastering these six cleaning methods for Alumina ceramic or zirconia ceramic Mill Jars ensures optimal equipment maintenance and longevity. Regular cleaning following each grinding session is imperative to preserve the operational efficiency of the ball mill and enhance its service life.

If you have any questions or inquiry about ceramic ball milling jars,welcome to contact us by email sales@inlabs.cc and we will reply you soon.