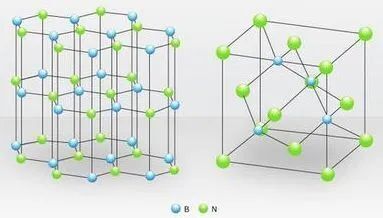

Boron Nitride is an advanced ceramic material with broad application prospects. It is a crystal composed of nitrogen and boron atoms, with a chemical composition of 43.6% boron and 56.4% nitrogen. It has four different variants: hexagonal boron nitride (HBN), cubic boron nitride (CBN), rhombic boron nitride (RBN), and wurtzite boron nitride (WBN).

Due to the fact that boron nitride material has a thermal expansion coefficient comparable to quartz, but a thermal conductivity that is 10 times that of the latter, it has excellent thermal shock resistance and can reduce the risk of cracking due to rapid temperature changes. It can be cycled several times at 20-1200 ℃ without any problem. In addition, boron nitride does not react with acids, alkalis, glass, and most metals, and has low mechanical strength, only slightly higher than graphite. However, there is no load softening phenomenon at high temperatures, and it can be processed by general metal processing machines. Therefore, it is indeed suitable for use as crucibles, vessels, liquid metal conveying pipes, and molds for casting steel for melting and evaporating metals.

Boron nitride can be used to manufacture crucibles for melting semiconductors, high-temperature vessels for metallurgy, semiconductor heat dissipation insulation parts, high-temperature bearings, thermocouple sleeves, and glass forming molds.

Currently, there are two types of boron nitride crucibles on the market:

1. PBN crucible

Usually, boron containing gas (BCl3 or B2H6) is used as the raw material and produced by chemical vapor deposition method. However, due to the high toxicity of B2H6, BCl3 is currently mostly used as the raw material. The boron containing gas undergoes pyrolysis (1500-1800 ℃) and reacts with NH3 in a high-temperature reaction chamber to form boron nitride solid. The chemical equation is as follows. Because pyrolysis reactions occur during the reaction, it is also known as a boron nitride crucible for pyrolysis (commonly known as a PBN crucible).

BCl3+NH3=BN+HCl

The growth process of PBN materials is similar to “falling snow”, where hexagonal BN flakes grown during the reaction continuously pile up on the heated graphite matrix (core mold). As time goes on, the stacking layer thickens, forming the shell of PBN. After demolding, it becomes an independent and pure PBN component, and when left on top of it, it becomes a PBN coating.

Due to the fact that PBN crucibles do not need to undergo traditional hot pressing sintering processes and do not require the addition of any sintering agents, they have a high purity (over 99.99%) and can be used at temperatures up to 1800 degrees Celsius under vacuum, with a maximum temperature of 2100 ℃ under atmosphere protection (usually using nitrogen or argon gas). They are mostly used for vapor deposition/molecular beam epitaxy (MBE)/GaAs long crystals and other purposes. In addition, due to the slow deposition rate, PBN crucibles are quite expensive (mostly small-sized crucibles).

2. Sintered BN crucible

The sintered BN crucible is made from hexagonal boron nitride and sintering aids (Y2O3, etc.) as raw materials. After forming, it is produced by high-temperature sintering, and also has good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength, which can resist the erosion of most molten metals.

However, due to the presence of sintering aids (1-6wt%) in the sintered BN crucible, its purity is not as high as that of PBN crucible. However, the price is relatively much cheaper and suitable for making large-sized crucibles, which can be used in inert gases such as argon or nitrogen at a maximum temperature of 2800 ℃; The stability in oxygen is poor and can only be used below 900 ℃.

In summary, although boron nitride crucibles may have a higher cost, they are quite practical in specific fields due to their excellent thermal shock characteristics, corrosion resistance, lubricity, high-temperature insulation, and high-temperature non reactivity.

For example, due to the excellent chemical stability of P-BN, as well as the high-temperature insulation characteristics, high thermal conductivity, and low thermal expansion performance mentioned above, it is very suitable for use as a material in strict environmental conditions such as semiconductor manufacturing, such as gallium arsenide, gallium phosphide, and indium phosphide. Meanwhile, due to its excellent mechanical processing performance, extremely high temperature resistance, and dielectric strength, boron nitride crucibles can also be used to make insulation materials or glass fixtures for various heaters, heating tube sleeves, and high-temperature, high-frequency, and high-pressure heat dissipation materials.

Precautions for product application and use:

1. Boron nitride is prone to moisture absorption, and the crucible cannot be stored in damp areas and cannot be washed with water. It can be directly wiped with sandpaper or wiped with alcohol.

2. The temperature used in the air should not exceed 1000 degrees, and the contact surface between boron nitride and oxygen will oxidize and peel off.