A probe card is a testing interface composed of probes, electronic components, wires, and printed circuit boards (PCBs). Depending on the situation, there may also be requirements for reinforcement boards, mainly for testing bare cores. According to different application scenarios and requirements, probe cards can be divided into various types, such as cantilever probe cards, vertical probe cards, MEMS probe cards, etc. Widely used in integrated circuit testing, semiconductor manufacturing, automotive electronics and other fields.

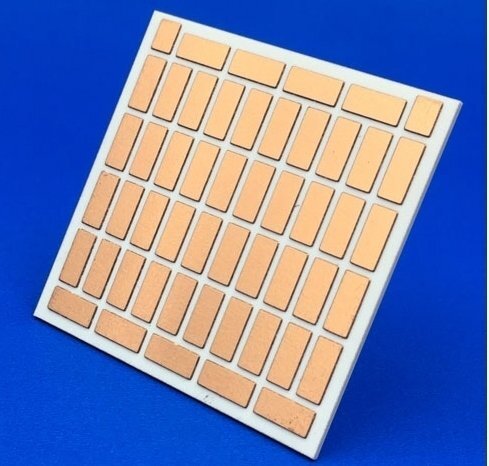

Ceramic substrate in probe card

The STF substrates are the core component of the entire probe card. The spatial conversion matrix plays a role in electronic connection spacing conversion and electrical signal transmission throughout the probe card, while providing sufficient mechanical/mechanical strength to support the applied force of several hundred to several thousand Newtons during the testing process.

The adapter board in high-end probe cards often uses ceramic substrates. Precision ceramic substrates have excellent electrical insulation, high thermal conductivity, high adhesion strength, and large current carrying capacity. And it has high strength, high hardness, and a wide temperature range, which can reach -55 ℃ to 850 ℃. The coefficient of thermal expansion is close to that of silicon chips. In a multi temperature testing environment, it is one of the effective solutions to solve deformation.

The ceramic substrate used for probe cards is generally a single-layer or multi-layer ceramic substrate with metallization. The multi-layer ceramic substrate is made by co firing high-temperature or low-temperature ceramics through multi-layer lamination and co firing, commonly referred to as a multi-layer ceramic space conversion matrix (MLC).

Type of ceramic substrate material for probe cards

1. High alumina porcelain

High alumina porcelain is a ceramic material mainly composed of aluminum oxide. It has excellent electrical performance and high-temperature stability, so it has been widely used in probe cards. High alumina ceramics have high strength and hardness, but high brittleness. Therefore, in the manufacturing process, it is necessary to pay attention to controlling process parameters such as sintering temperature and time.

2. Silicon nitride ceramics

Silicon nitride ceramic is a ceramic material mainly composed of silicon nitride. It has excellent electrical performance, high temperature stability, and oxidation resistance, so it can replace high alumina porcelain as a substrate material in some application fields. Previously, Kyocera launched a Starceram N3000 P high-performance silicon nitride ceramic plate, which combines the necessary strength, low wear, and the ability to slide back and forth in the guide hole, with the best characteristics suitable for producing probe cards.

![]()

3. Other material types

In addition to high alumina ceramics and silicon nitride ceramics, there are also some other types of materials that can be used to manufacture ceramic substrates for probe cards. For example, magnesium oxide ceramics have excellent electrical properties and high temperature stability; Boron nitride ceramics have excellent high-temperature resistance and oxidation resistance; Silicon carbide ceramics have excellent characteristics such as strength and hardness. These material types can also be applied in certain application fields, but they need to be selected based on specific usage environments and performance requirements.