Small ball mills exhibit compact dimensions, high operational efficiency, and ease of maintenance, rendering them indispensable equipment for powder grinding, mixing, and dispersion in laboratory and small batch production settings following material crushing. Their versatile nature enables the processing of materials spanning the spectrum from soft to hard, brittle to tough. Moreover, these mills can be tailored to various capacities, accommodating grinding tasks ranging from a few grams to several tons per operation. Below, we delve into the distinctive features of horizontal and planetary ball mills to facilitate informed decision-making.

Horizontal Ball Mill:

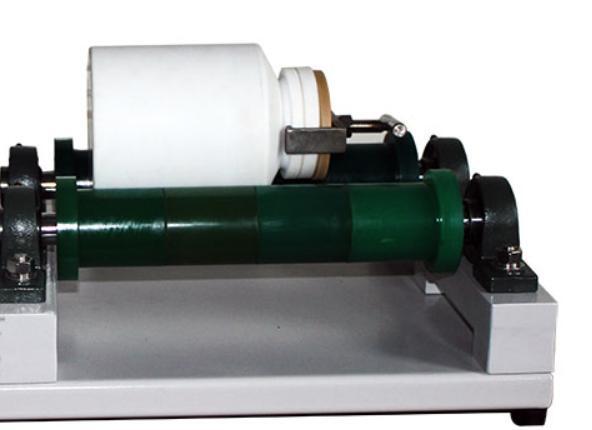

The horizontal ball mill machine, characterized by a drum-type configuration, revolves around its axis, housing grinding balls within the cylinder. As the grinding cylinder rotates, it manifests three operational states: descending at low velocity, optimal throwing velocity, and excessive speed leading to tight confinement. During descent, material pulverization primarily stems from grinding effects; in the throwing phase, impact effects dominate; and in the tightened state, material-grinding interactions diminish, compromising crushing efficacy. The prevailing velocity is often termed the critical speed.

Planetary Ball Mill:

A planetary ball mill machine, distinguished by its rotation and revolution mechanism, employs controllable angular velocities to accommodate materials of varying hardness. Its operation involves opposing self-rotation and common rotation speeds, with ball milling canisters evenly distributed across a large disk. The planetary action augments the weight of both the grinding ball and material, intensifying interaction forces and enhancing grinding efficacy. This heightened interaction promotes effective grinding, even during descent, generating ample stress for optimal grinding outcomes. Furthermore, grinding efficacy hinges on the sliding velocity during contact between grinding balls and material. While drum-type ball mills are constrained by critical speed limitations, planetary ball mills enable the expulsion or dislodgment of material and balls at elevated rotational speeds due to increased masses. Consequently, this configuration fosters favorable conditions for ultrafine grinding. Notably, the self-rotation and common rotation speeds of planetary ball mills can be tailored to suit specific requirements, offering a customized approach to milling operations.

If you have request of regular zirconia or alumina ceramic ball mill jar and lid set, you can send your inquiry detail for us at sales@inlabs.cc.